ZENITH AIRCRAFT COMPANY FACTORY VISIT

South of the Border Down Mexico, Missouri Way!

- By John Burroughs

Sport Pilot Magazine

September 1994

Back in Spring of 1992 one of the industry's major players, Zenair Ltd., of Midland, Ontario, Canada, announced the opening of a new plant in Mexico, Missouri, of all places. At the time, some wondered just what Zenair was up to. The company explained that they were simply outgrowing their 20,000 sq. ft plant in Ontario, but why Missouri? And why Mexico? And why did they call it that? I had to know!

| In Spring of 1992, Zenith Aircraft, Inc. opened its new 11,000 sq ft plant in Mexico, Missouri. |  |

Zenair is one of the few homebuilt kit manufacturers which has defied the unpredictable and mercurial nature of the industry to become a real long-term success story. Thanks to an uncommonly common-sense approach to both design and business, Zenair has managed not only to endure, but to prevail. The firm is currently celebrating its 20th year in business, and with continued strong kit sales and the impending certification of its CH 2000 two-seater, it's been a banner year for them in more ways than one.

As you probably know, the guiding force behind Zenair is designer Chris Heintz. A native of Strasbourg, France, Heintz boasts a degree from Switzerland's top engineering school and extensive experience in the aerospace industry. In the 1960s, Heintz worked for Aerospatiale on the Concorde project. Later, he went to work for Avion Robin Aircraft, where he eventually became chief designer. It was at Robin that Heintz' interest in light aircraft blossomed, and he often spent time working on his own projects after hours.

| Thanks to the basic design of Zenith aircraft, known as Zenairs in Canada, many of the components produced at the plant are fabricated by hand using precision templates and simple tools. |  |

It was during his tenure at Robin that Heintz designed his first homebuilt aircraft, a lightweight two-seater called the Zenith 200, the plans for which quickly became popular beyond all expectations. At Robin, Heintz also made a name for himself as he guided the company's transition from dated all-wood planes to thoroughly modern two-and four-seat all-metal aircraft. After leaving Robin - the company was just growing too big for his liking Heintz worked for Brazilian aircraft manufacturer Embraer, and later for de Havilland, in Toronto.

Following his bliss instead of his pocketbook, Heintz left de Havilland and in1974, founded a homebuilt kit company called Zenair. He's been there ever since turning out great-flying little homebuilts, and he's likely to be there a while longer doing the same, and then some.

Though he's designed a wide variety of kit aircraft, twelve in all at last count, Heintz is most often associated with all-metal low-wing tricycle gear planes which share many other traits in common (more on that later). Today the company produces two very popular homebuilts, the high-wing STOL CH701 and the low-wing Zodiac CH 601 (in a couple of different permutations), as well as some of the best floats in the industry. Over the years, Zenair has also turned out an ultralight, the Zipper, and a high-performance acrobatic model, the CH 180 "Super Acro Z."

| Before a part ships, it is hand finished and then double-checked to make sure it meets the highest standards. |  |

Regardless of what shape the final kit takes, however, any Zenair design is as much the result of a construction philosophy as it is the product of a company. This philosophy, as the company's name seems to imply ("Zenith" is actually an anagram of "Heintz"), embraces the ideals of efficiency, simplicity, and single-mindedness. Whether intentional or not, the Zen connotation is fitting. Zenair's aircraft are uncommonly well designed, featuring solid, straightforward design at the expense of fancy options that add expense, complexity, and little more. It's a philosophy that, when you're talking about aircraft design, really makes sense to me.

Zenith Aircraft has now imported this tradition to the US. Their new Missouri plant is set up to produce the same kind of no-nonsense designs their Canadian sister plant has been turning out for the past two decades.

A couple months ago I found myself aboard a big old jet airliner carrying me to St. Louis, Missouri, the city which lies at, and sometimes underneath, the confluence of the mighty Mississippi and Missouri Rivers. On final approach in our 737, we passed right by the McDonnell Douglas plant at Lambert field. It reminded me right off the bat that St. Louis is a city with a lot of aviation history.

By the time I got to St. Louis, rented a car and hit the road east towards Mexico, which is 95 miles from downtown St. Louis, I was ready for anything. I ran into "anything" about 50 miles out of town. It was the "Elvis is Alive" Museum. I was already late, so I decided to wait until my return trip to stop in for a couple of their 49-cent burgers. The sign out front said they had proof the king was alive and well. I figured that since he was healthy, he could probably manage to stay alive a few more days until I got the chance to pay the museum a call.

I drove into Mexico just before sunset and was greeted by a charming old fashioned Midwestern town complete with tree lined streets and rows of beautifully refurbished turn of the century homes. It's a great little town, as I would soon discover, offering a combination of the kind of slow paced middle America charm I thought had disappeared long ago, along with thoroughly modern business sensibilities. The result is a place that's nice, and affordable to live in, and that is very trade friendly at the same time.

Soon, I found my hotel, a fantastic little bed and breakfast called the Hylas House. The establishment, a renovated 1900s-era home, is owned and operated by Tom and Lynda Hylas. If you ever make it out to Mexico, you've got to stay there. Just be sure to make your reservations early: (573) 581-201 1. They have a lot of return business (did I mention Lynda's Belgian waffles!).

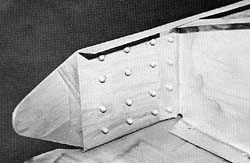

| Wing spars are pre-assembled at the Midland, Ontario, factory with conventional bucked aircraft rivets. Note that the spar for this Super Zodiac has the dihedral built in. |  |

The next morning I made it out to the factory, situated on the grounds of Mexico Memorial Airport, and I immediately saw another good reason Zenith chose Mexico: the airport is just great. With two long runways, all services, precious little traffic, and uncontrolled airspace for miles and miles around, the place is an open invitation to go up and go flying. Not that I ever need an invitation!

When I pulled up to the impressive new building, featuring huge, bifold doors offering direct access to the runway, things were even more clear for me. It would be hard to imagine a better setting for building airplanes. Cessna and Beech, among many, many others, would likely agree. The Midwest has treated them just fine over the years.

One prime advantage of the area is that it's so centrally located that the company can realistically serve both left and right coasts and the bread basket, too. This is a big advantage for the company's customers, who can more easily make the trip to the factory to check out the goods (a trip I strongly recommend to anyone seriously interested in a kit). The viability of the central location theory was confirmed at last fall's first annual Zenith fly-in when more than 100 airplanes showed up for the festivities. That's a phenomenal number of planes for a factory fly-in, and it goes to show the loyalty of Zenair customers.

| The interior of the plant is set up for efficient production, storage and shipping of components to customers. |  |

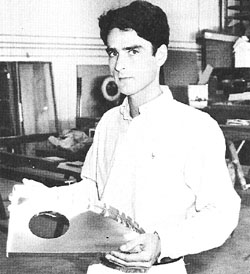

I was greeted at the door by Zenith President Sebastien Heintz, and he introduced me to the crew and began to show me around the place. Sebastien, a pilot and a graduate of Georgian College, has been working with his father in the business for years now. When I asked him he told me that while he's never built an entire kit, he's personally built hundreds, if not thousands, of components for every kit Zenair's ever produced. Even Sebastien's flying experience has "Zenair" all over it. He learned to fly in Canada in a Zenair Zipper, the company's ultralight, and he has hundreds of hours in a variety of other Zenairs since then. Nicholas Heintz, another of Chris' sons, is the production manager at the plant, and one of the company's chief demonstration pilots, too. Nick, with a B.S. from the University of Toronto, flew the subject plane in formation on several of our photo shoots while I was visiting the factory, though his main charge is making sure that kits go out on time. He's expert at both duties.

After a brief chat about the progress the company has been making over the past year and a half, Sebastien took me out from his office to the main factory.

The brand new building is just the right size, it seems to me, with plenty of room for growth, as growth is warranted, while not being so huge you get lost going from one end to the other. This is all in keeping with the company's "less is more" philosophy, which seems to make everyone, employees and customers, happy.

As Sebastien escorted me around the factory, that approach became more and more apparent to me. I was really surprised by just how simple the Zenith manufacturing process is, more so because the process leads to such easy building, great flying aircraft. That, of course, is one of the chief advantages of sheet metal construction. You're working with a material with an extensively documented performance history and you can see with your own two eyes, or with simple, commonly used equipment, just what kind of component you have before you. Though wood and fiberglass have their advantages, it's hard to detect flaws in either material. So metal makes sense in more ways than one.

| Bound for the tropics, this subassembly has been heavily zinc chromated for corrosion resistance. |  |

For those of you not familiar with the company's products, Zenair, and now Zenith, is synonymous with riveted all-metal construction. Chris Heintz developed the technique as a simple, straightforward way for his customers, which included many first-time aircraft builders, to put together their kit the right way, and to do so in short order. Today, the sleek CH-601 and STOL CH-701 are the company's main homebuilt products, though they also offer aluminum floats and a variety of plans and custom kits for other aircraft, as well as their biggest project to date, the soon-to-be certified CH 2000 (see related story elsewhere in this issue).

The means to the end of Zenith's easy-building all-metal aircraft is the AVEX rivet, a consumer aircraft rivet, if you will, that allows even unskilled homebuilders to make consistent, reliable connections. Though aircraft purists might look askance at the use of these fasteners, Zenair's track record speaks for itself. With more than 20 years worth of airplanes up and flying, it's clear that the method works and works reliably well. This is borne out by the fact the company's CH 2000 is receiving FAA certification making extensive use of these blind AVEX rivets.

About the only components on Zenith aircraft which don't make use of the AVEX rivets are the spars, which are almost always factory pre-constructed. These critical components are constructed from aluminum stock with traditional bucked aircraft rivets, and if anything, they're way overbuilt, with AN bolts connecting the center spar to the outboard sections. Even the dihedral - on those models with this characteristic - is built right into the component. Even most of Zenith's customers who choose to build from plans - yeah, those kind of homebuilders still exist- frequently order the factory built spars, and it's easy to see why.

But the most numerous components built at the Zenith factory are, of course, wing ribs. These are built by hand with flanged tightening holes. Once they're finished, they're individually inspected for any irregularities.

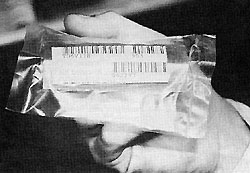

Then, as is the case for every component built at the factory, each one is barcoded for instant identification. Without this kind of quality assurance and tracking system in place, certified aircraft production would be impossible, as the FAA demands, and rightfully so, strict compliance from aircraft manufacturers. That way, if any parts are found to be faulty, the entire batch can be tracked all the way back to the customer, and a correction made before it causes any problems. Though the FAA requires no such system for kit makers, Zenair has had such a program in place for years now anyway. Make no mistake about it: Zenair's kit customers appreciate the benefits of the system when they order parts - and get instant information on availability and pricing - as well as every time they get in their airplane, confident in the knowledge that they enjoy fantastic factory support.

Tying the whole construction scheme together are the aluminum alloy skins, which come pre-bent and many of which come with pre-drilled pilot holes. The homebuilder has only to line up the holes, drill, and, voila, before he knows it, he has a wing, or horizontal stabilizer, or what have you. The process is simple and fast, and it builds reliably straight, strong parts.

| Zenith President Sebastien Heintz holds up a finished leading edge rib for a CH-701. |  |

As far as I could tell during my tour, this kind of attention to quality and to detail is the rule at Zenith, so no matter what component you're talking about, you can be sure it's equally well designed and well made.

The same goes for the manufacturing of sub-assemblies, which is one of Zenith's raison d’Ítre. Unconstrained by the FAA's 51-percent rule for the amateur-built category, customers in Europe and elsewhere throughout the world (there are, according to the factory, Zenairs flying in more than 48 countries around the globe) can get kits in a much more finished state than we can in the States. Zenith is all too happy to supply these customers with completely assembled components or with almost ready to fly kits which require just a few hours of light assembly before they're ready to take to the sky.

If there are any problems, and I'm told there aren't many, Zenith's customer support is at or near the best in the industry. Plans and construction manuals are professionally prepared packages, with illustrations, explanations, and diagrams so that even the first timer would have little or no trouble understanding. Even the company's information packages are works of art, with outstanding graphics, scale cutaway drawings, and clear descriptions of what putting together a Zenith kit is all about.

| Heintz exhibits a nose gear assembly for the CH-701. |  |

Sebastien tells me that many customers on the fence between a Zenair and some other design have been convinced to go with model "Z" after a tour of the factory, and I don't doubt it for a second. After I'd been there for a few hours, after I'd seen firsthand how their kits are built and how they've supported, I was convinced.

Okay, but why do they call it "Mexico?" No one's really quite sure, but one story goes that a long time ago a practical joker put up a road sign alongside the railroad tracks passing through town. With an arrow pointing southwest, the sign read: "Mexico: 1324 miles." All that the passing trains could read was the "Mexico" part, so that's what the engineers started calling it, and it stuck. It works for me.

| Part are computer bar coded so it's easy for workers, and customers, to find out what parts are in stock and how much they cost. |  |

As for the "Elvis is Alive" Museum, well, I'm not so easily convinced when it comes to this premise. The 49-cent hamburgers were good, but my guess is that Elvis won't be enjoying one of them any time too soon. So, if you want the real thing, keep going right past the Elvis museum and head west until you get to Mexico. And remember, if you hit Texas, you've gone too far.

Sport Pilot magazine, by John Burroughs

Pages 22 – 27, September 1995

© Sport Pilot 1995. Call 800 562-9182 for subscriptions.The views, opinions, accuracy of presented information or technical data do not necessarily reflect those of Zenith Aircraft Company. The information is provided strictly for entertainment and education.

Zenith Aircraft at Work and Play around the World... Click here for photos and stories Zenith Aircraft

Company |