'SEVEN DAY WONDER'

ZODIAC AT SUN'N FUN FLY-IN

BUILDING &

FLYING AN AIRCRAFT IN ONE WEEK!

At the EAA Sun'n Fun fly-in (Lakeland, Florida) during the

week of April 18 - 24, 1993, aviation enthusiasts saw a complete airplane built, and

flown, within a period of just seven days!

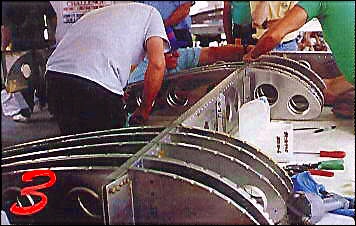

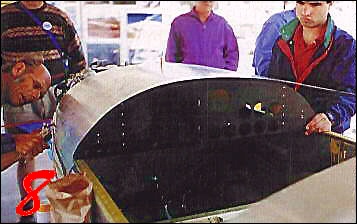

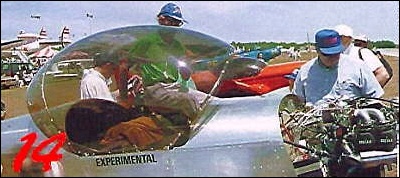

Kit manufacturer Zenith Aircraft Company supplied a

complete kit and oversaw assembly of a complete Super ZODIAC CH 601 HDS aircraft at the

convention's sheet-metal workshop during the fly-in.

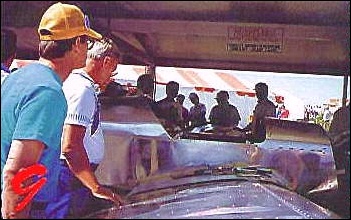

Visitors to the fly-in were able to see an aircraft come

together before their very own eyes as staff and volunteers rushed to build and finish an

aircraft in a week!

Assembly of the off-the-shelf kit started on Sunday, April

18, and continued through to the following Saturday, when the completed ZODIAC aircraft

was flown on its maiden flight during the final airshow of the one-week fly-in. Chris

Heintz, the aircraft's designer, had the honor of test flying the newly-built plane.

Zenith Aircraft staff volunteered their time in leading the assembly project, with the help of

local volunteers.

The Super ZODIAC CH 601, an all-metal kit aircraft designed

by aeronautical engineer Chris Heintz, was chosen for this challenging project primarily

because it is easy to build, utilizing a simple and proven all-metal assembly process.

Building the ZODIAC kit required only basic tools, and did

not call for jigs or special skills, making kit assembly quick and relatively easy. The

metal parts that made up the kit are pre-formed at the Zenith Aircraft factory, ready for

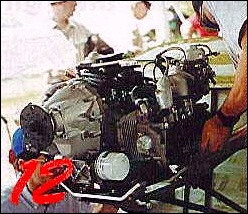

assembly. The ZODIAC aircraft was equipped with the 80-HP Rotax 912 engine and a basic

factory panel. With the 80 horse-power engine, the sleek two-seater cruised at a brisk

135-MPH, burning less than four gallons per hour.

Having already successfully completed similar projects in

the past, the kit company was confident that the aircraft would be ready to fly at the end

of the week: In 1978, another Heintz design, the Zenith CH 200, was built in seven days at

the Oshkosh Fly-In, and several STOL CH 701's have been assembled and flown at previous

Sun'n Fun fly-ins, being awarded the show's "Best Workshop" by Sport Pilot

magazine (1990). At the 1988 World's Fair in Vancouver, a complete ZODIAC was built in

twelve days.

The educational project was an excellent opportunity for

first-time builders and aviation enthusiasts to learn all about building and flying their

own aircraft - by following the assembly of a complete aircraft in just one week. Designer

Chris Heintz was on hand all week to explain the Zodiac's design and construction and to

oversee assembly of the "seven day wonder".

Why does Zenith Aircraft sponsor "Seven Day

Wonder" construction projects?

Chris Heintz explained: "We started it as a challenge: To prove that it

could be done. Also, I think the construction project fills a void at the fly-in

conventions - where there are only completed aircraft to see. This project shows visitors

that it is possible to build an aircraft without special skills or tools, and allows them

to follow the full construction of an aircraft during a single week - from start to

finish."

"Building aircraft is what EAA [the Experimental

Aircraft Association] is about - and this type of project shows the average fly-in visitor

that he or she can build their own aircraft!" Explained Heintz. "While

we all love to look at finished aircraft, one has to realize what is involved in getting

the aircraft to its finished state.

"Obviously, the project is also an excellent

promotional tool. It proves how quick and easy our kits are to assemble, and validates my

claims about my designs' construction simplicity. I'm somewhat surprised that no other

manufacturers have attempted a similar project, but maybe they're not as confident about

being able to finish one of their kits within a week.

"We don't attempt a 'Seven Day Wonder' project

every year: First, we've proven that it can be done, and it's also a lot of work to

organize. When we're not doing one of these projects, we like to spend time at the

workshop showing potential builders some of the basics in metal construction. During a

seven-day project, I can't spend too much time talking with visitors - we have to

concentrate on getting the project completed."

[Back]

[ZODIAC CH 601]